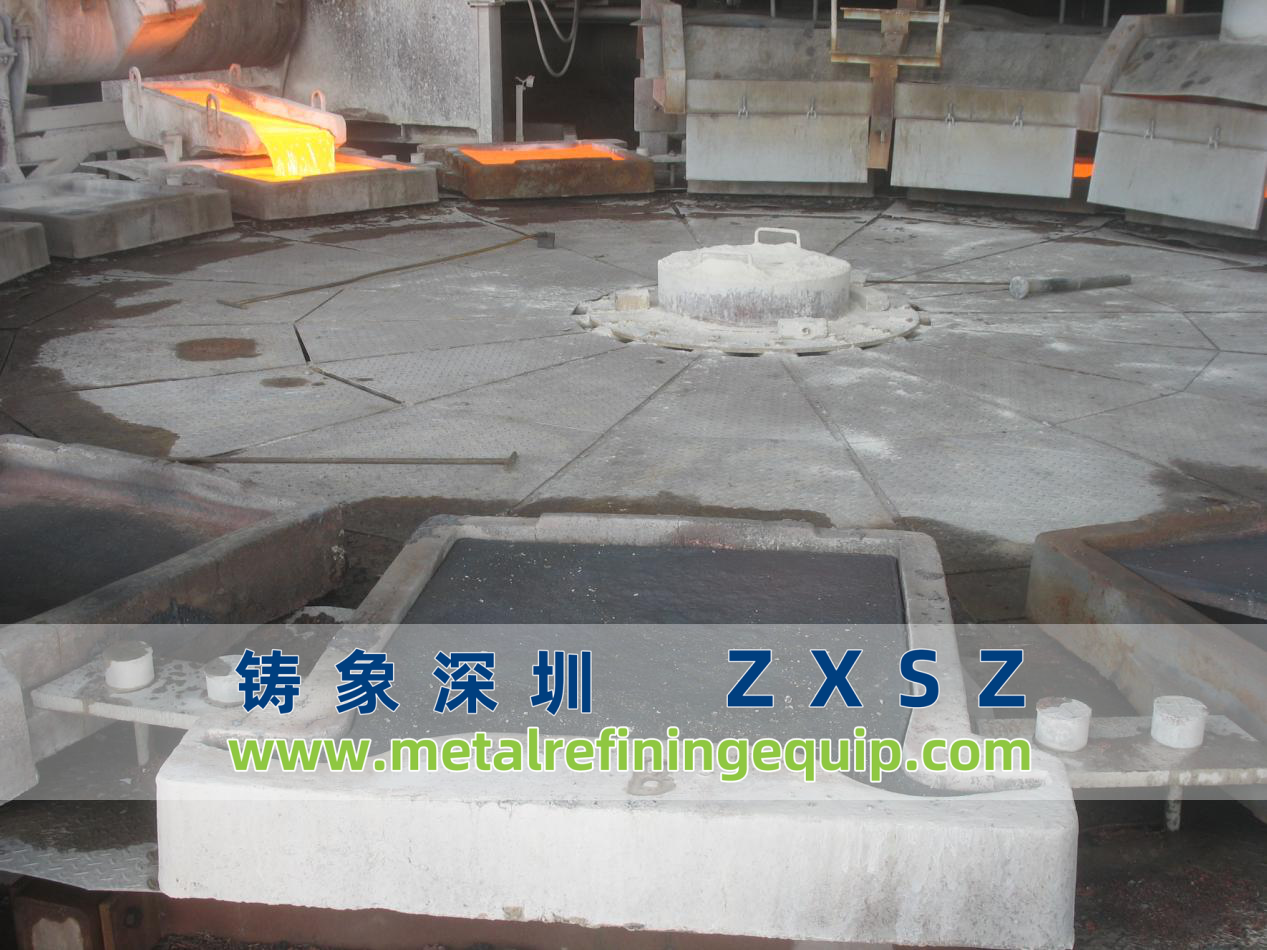

100,000 t/a Large-scale Copper Processing Project 16-unit Double-mold Disk Fully Automatic Quantitative Casting Machine — Daye Nonferrous Metals Copper Industry Co., Ltd.

| Main Parameters | 16-Mold Double Disc | 16-Mold Single Disc |

|---|---|---|

| Disc Diameter | 2×9600mm | 9600mm |

| Casting Capacity | 85-100t/h (each plate weighs 380kg) | 45-50t/h (each plate weighs 380kg) |

| Anode Plate Weight | 175/354/360kg per plate | |

| Anode Plate Weight Accuracy | 98% of anode plates have a weight within ±1-2% | |

| Anode Plate Qualification Rate | 98% | |

| Remarks | 1. For double disc use: one disc casts 175kg per plate, the other casts 360kg per plate or 354kg per plate; 2. The weight accuracy of anode plates improves as the plate weight increases. | |

ZXSZ – China’s Global Metal Casting Technology

ZXSZ is a leading manufacturer in China and an international supplier of casting and pouring equipment for non-ferrous metals, dedicated to providing high-quality solutions for the global metal industry.

1. Core Product: Automatic Disk-Type Casting Machine System

Our flagship product is the automatic disk-type casting machine system, available in both double-disk and single-disk models, specifically designed for the production of copper anodes.

2. Key Technical Parameters

We prioritize efficiency, precision, and stability, with parameters that meet large-scale industrial demands:

- Pouring capacity: Up to 100 tons per hour

- Anode weight: 175 g, 354 g, 360 g per unit (multiple specifications available)

- Weight accuracy: 98% of products fall within a margin of ±1 – 2%

- Anode qualification rate: 98%

3. Technology & Production Advantages

ZXSZ’s casting technology transforms traditional processes into a modern, reliable workflow, with core advantages including:

- High efficiency: Supports large-scale production with a pouring capacity of 100 tons/hour.

- Stable precision: Ensures consistent product quality with 98% weight accuracy and qualification rate.

- Industrial reliability: Adaptable to long-term, high-intensity industrial operations.

- Automation & safety: Reduces manual intervention, lowers operational risks, and improves production continuity.

4. Frequently Asked Questions (FAQ)

Q1: Is ZXSZ a manufacturer or a distributor?

A1: We are both a well-recognized manufacturer in China and a global trader of casting equipment, integrating R&D, production, and international supply.

Q2: Can the equipment be customized according to production capacity?

A2: Yes. We tailor the configuration of the round disk and the anode weight to match the specific production requirements of each plant.

Q3: What advantages does ZXSZ have over other suppliers?

A3: Our competitive edges lie in:

- Proven technology verified in international projects;

- Energy-efficient design to reduce operational costs;

- High precision to ensure product consistency;

- Global technical support for timely after-sales service.

Address: No. 173 Xiangjiang Avenue, Development Zone, Zhanggong District, Ganzhou City, Jiangxi Province, China

Phone/WhatsApp: +86 199 5432 2149

Email: zxszchina@gmail.com

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.