Fully automatic disc quantitative casting machine

【 Overview 】

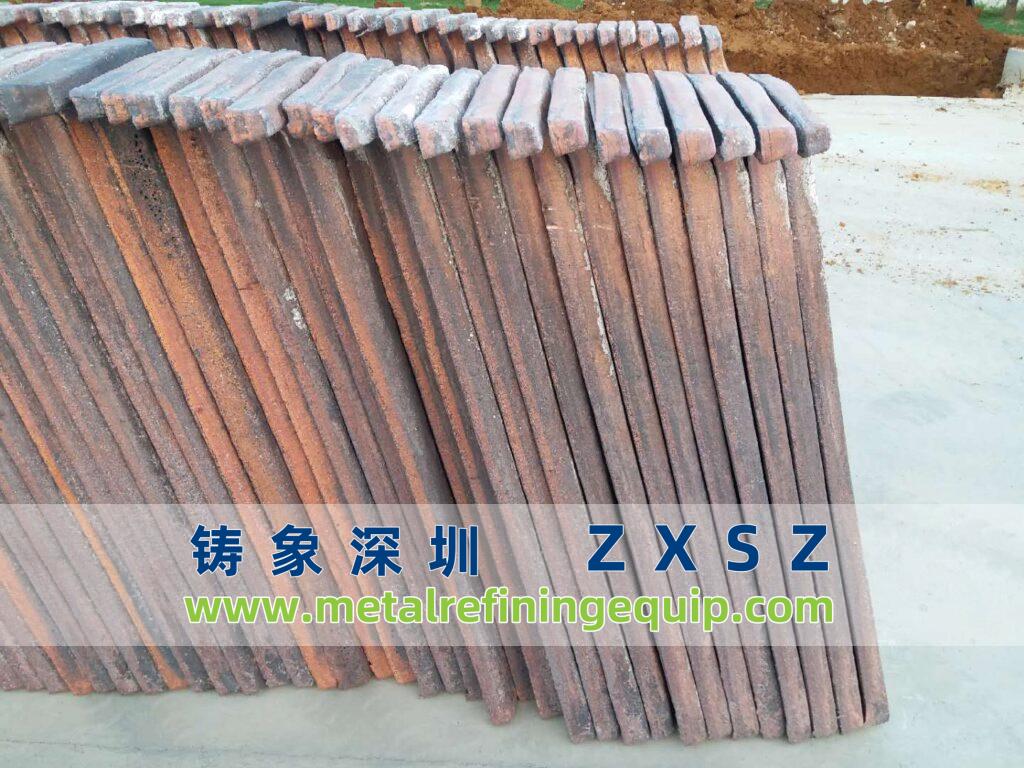

The most basic function of a casting machine is to cast the molten metal after smelting into solid metal with specific shape, specifications and weight requirements. Since users have very different requirements for these requirements and casting capabilities, the functions, structures, performances and prices of casting machines used by various users and occasions are also very different. In addition to the functions of general casting machines, the fully automatic disc quantitative casting machine also has the following functions:

Fully automatic – the entire process of molten copper flowing out of the anode furnace through the chute, tundish, casting ladle, casting mold, spray cooling system, pre-lifting device, lifting device, lifting plate, cooling in the water tank, conveying to the tail of the water tank and spraying is completed automatically;

Quantitative casting – the operator can set the weight of the anode plate according to the user’s requirements, and the weight of the cast anode plate can fully meet the requirements.

【 Equipment composition】

The fully automatic double disc/single disc quantitative casting machine is a large-scale production equipment that integrates mechanical, electrical, hydraulic, pneumatic, automatic control and other technologies and equipment. The equipment consists of several subsystems. These include the casting and weighing subsystem, the disc and its drive subsystem, the spray cooling subsystem, the spraying subsystem, the extractor and cooling water tank subsystem, the hydraulic subsystem, the PLC control subsystem, the human-machine interface control subsystem, etc.

【 Main features】

1. Adopt time-sharing precise quantitative control method to ensure the accuracy of quantitative casting.

2. Unique mold status setting function, including the setting of bad mold, waste anode plate and empty mold. When bad mold, sticky mold, waste anode plate and other phenomena occur, you only need to set the bad mold and waste plate marks to skip their casting without affecting the casting of other molds; once the bad mold has been replaced with a good mold, the sticky mold has been removed, and the waste anode plate has been removed, these molds can be restored to empty molds (good molds) and continue to be used for casting to avoid reducing the casting capacity.

3. The disc body is driven precisely, with smooth acceleration and deceleration to avoid flash and ensure the physical specifications of the anode plate.

4. Full Chinese operation interface, genuine INTOUCH software support, stable operation and intuitive operation.

5. The conveyor chain of the cooling water tank can be reversed, which is convenient for handling when the board falls.

6. The stacking quantity of anode plates can be set to facilitate forklift dispatching.

7. The cooling water is controlled by the mold temperature detected online to extend the service life of the mold.

8. The power-off protection function of the hydraulic station enables the casting ladle to be reset after a sudden power outage.

9. The weight of the anode plate can be easily adjusted.

10. With only appropriate local adjustments, the casting machine can be suitable for casting anode plates of various specifications. This is very suitable for the current domestic users’ development requirements of switching from small plates to large plates.

【 Application and performance】

The casting machines developed, manufactured, installed and debugged by Ganzhou Jinhuan Casting Equipment Co., Ltd. have been applied in China. The application practice shows that the fully automatic quantitative casting machines provided by our company are advanced, practical, safe, reliable, easy to operate, have excellent performance and low price, and can bring users maximum economic and social benefits. At the same time, our company’s excellent service quality, strong technology, economic strength, excellent equipment and manufacturing level are also recognized by users, thus gaining wide acclaim.

【 Application examples】

Application Example 1 (16 modules)

| Main parameter name | M16 double disc type | M16 single disc | illustrate |

| Disc diameter(mm) | 2 × Φ9600 | Φ9600 | |

| Casting capacity (tons/hour) | 85-100 | 45-50 | |

| Anode plate weight (kg/piece) | 380-450 | ||

| Guaranteed anode plate weight accuracy | 98% of the anode plate weight error is within ±1% of the plate weight | ||

| Anode plate qualification rate | 98% | ||

Application Example 2 (18 modules)

| Main parameter name | M18 double disc type | illustrate | |

| Disc diameter(mm) | Φ10090 | ||

| Casting capacity (tons/hour) | 85-110 | ||

| Anode plate weight (kg/piece) | 380-450 | ||

| Guaranteed anode plate weight accuracy | 98% of the anode plate weight error is within ±1% of the plate weight | ||

| Anode plate qualification rate | 98% | ||

Application Example 3: Daye Nonferrous Jinsheng Copper Co., Ltd. started production in February 2007

| Main parameter name | M16 double disc type | M16 single disc | illustrate |

| Disc diameter(mm) | 2 × Φ9600 | Φ9600 | 1. Double discs: one for casting 175 kg/block, the other for casting 360 kg/block or 354 kg/block; 2. The weight accuracy of anode plates increases with the increase of plate weight. |

| Casting capacity (tons/hour) | 85-100 | 45-50 | |

| Anode plate weight (kg/piece) | 175/360/354 | ||

| Guaranteed anode plate weight accuracy | 98% of the anode plate weight is within ±1-2% | ||

| Anode plate qualification rate | 98% | ||

Application Example 4: Baiyin Nonferrous Group Copper Company put into production in June 2009

| Main parameter name | M16 single disc | illustrate | |

| Disc diameter(mm) | Φ9600 | After this equipment was put into use, the company’s original three equipment were all stopped from use. | |

| Casting capacity (tons/hour) | 45-50 | ||

| Anode plate weight (kg/piece) | 320 | ||

| Guaranteed anode plate weight accuracy | 98% of the anode plate weight is 320±1-2% | ||

| Anode plate qualification rate | 98% | ||

Address: No. 173 Xiangjiang Avenue, Development Zone, Zhanggong District, Ganzhou City, Jiangxi Province, China

Phone/WhatsApp: +86 199 5432 2149

Email: zxszchina@gmail.com

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.