Introduction to silver ingot casting machine and ingot casting machine models

15kg and 30kg Silver Ingot Casting Machine

| Design Capacity | 15kg | 3.3~4 tons/24 hours (15~18 heats), hot furnace status, silver powder material | |

|---|---|---|---|

| 30kg | 4~4.8 tons/24 hours (15~18 heats), hot furnace status, silver powder material | ||

| Silver Ingot Weight | 15±1kg/ingot, 30kg/ingot | ||

| Hydraulic Pressure | 12MPa | Control System | PLC Control |

| Equipment Weight | Total weight approx. 30,000kg, heaviest device (mold car) approx. 5,000kg | ||

| Overall Dimensions | Complete machine: 12000×9300×3200mm, largest part (mold car): 10000×1000×2700mm | ||

-

- Model One: Melting and Casting Type (Dual-Purpose Machine)

-

- Utilizes medium frequency furnace for melting, capable of casting 15kg vertical molds and 30kg flat molds.

-

- Features automatic mold release, robotic arm for fetching, and automatic post-processing (water cooling, trimming silver heads, grinding, polishing, marking), and finally palletizing.

-

- Floor space required: 15 meters in length, 10 meters in width, totaling 150 square meters.

-

- Investment: RMB 4 million in total, excluding construction costs.

-

- Capacity: 1.5-2 tons per 8 hours.

-

- Mold material: Cast iron.

-

- Mold changing method: Automatic mold change by cart.

-

- Model One: Melting and Casting Type (Dual-Purpose Machine)

-1024x768.jpg)

-

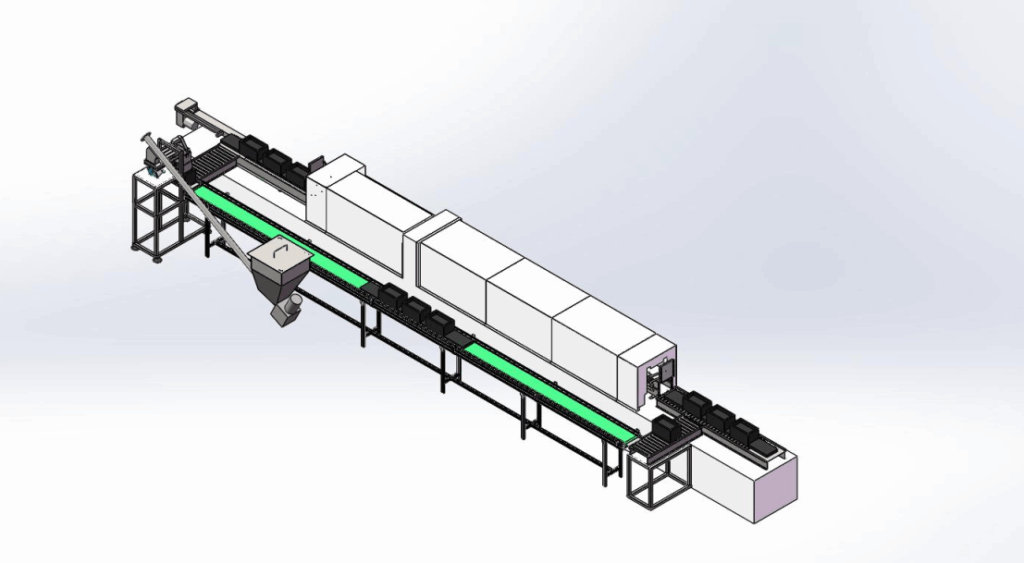

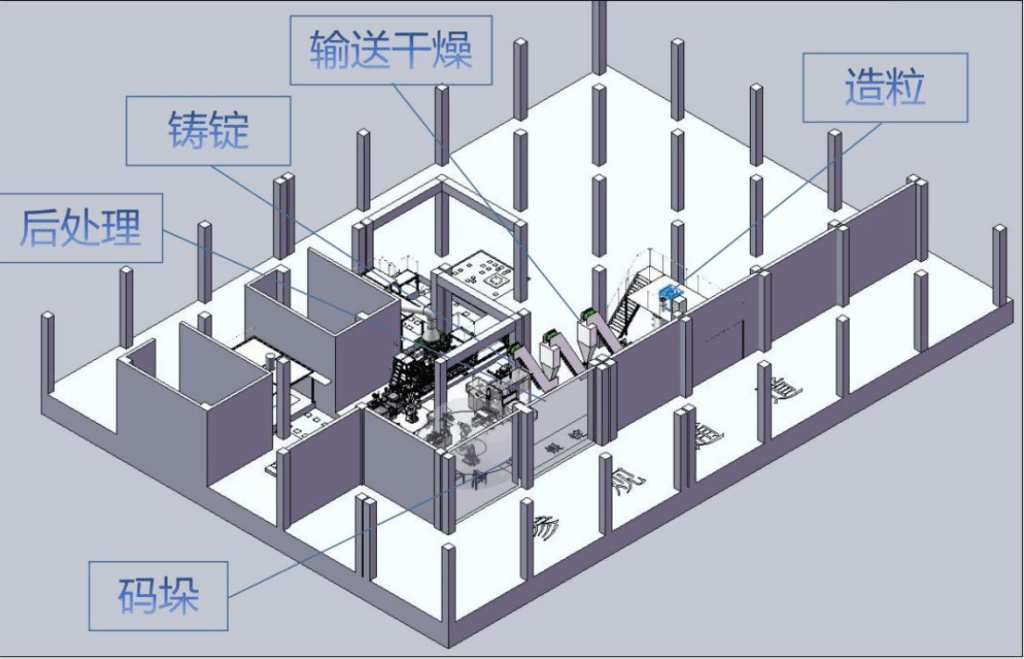

- Model Two: Tunnel-Type Static Ingot Casting

-

- Silver powder goes through granulation and drying first, then automatically weighed and added to the mold. It uses tunnel-type medium frequency induction melting and casting, with cooling performed within the tunnel.

-

- The mold is removed from the furnace when its temperature drops below 400°C, followed by demolding and post-processing.

-

- Floor space required: Including granulation, ingot casting, and post-processing, it requires 20 meters in length, 20 meters in width, totaling 400 square meters.

-

- Investment: RMB 6 million in total, including granulation, ingot casting, and post-processing, excluding construction costs.

-

- Capacity: 1.0-1.5 tons per 8 hours.

-

- Mold changing method: Manual mold change.

-

- Model Two: Tunnel-Type Static Ingot Casting

Model Three: Alternating Left-Right Static Ingot Casting

-

- Silver powder goes through granulation and drying, then automatically weighed and added to the molds in a dual-position ingot casting furnace using medium frequency induction melting.

-

- Dual molds alternate between melting processes inside the furnace and are cooled via water jackets; demolding occurs when the mold temperature exceeds 400°C.

-

- Post-casting water cooling and processing can be done either inside the furnace or after removal.

-

- Floor space required: 24 meters in length, 10 meters in width, totaling 240 square meters (length can be adjusted based on site layout).

-

- Investment: RMB 7 million in total, including granulation, ingot casting, and post-processing, excluding construction costs.

-

- Capacity: 1.4 tons per 8 hours.

-

- Mold changing method: Manual mold change

Address: No. 173 Xiangjiang Avenue, Development Zone, Zhanggong District, Ganzhou City, Jiangxi Province, China

Phone/WhatsApp: +86 199 5432 2149

Email: zxszchina@gmail.com

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.