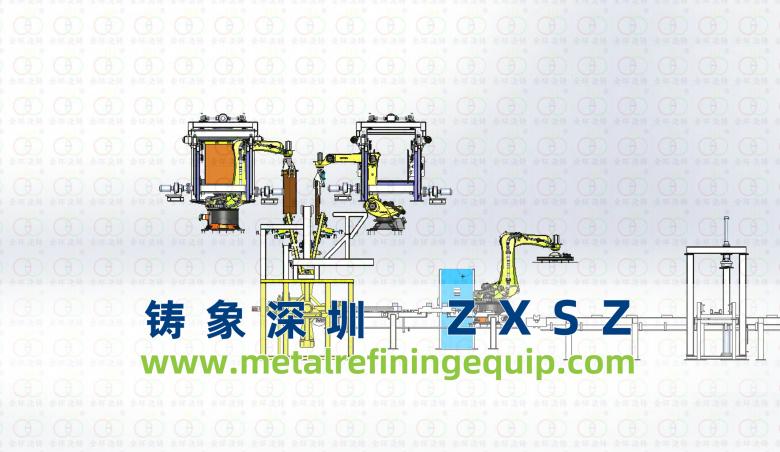

robot stripping unit

Equipment Technical Parameters and Specifications

- 【Equipment Type】 Robot-type

- 【Number of Cathode Plates per Cell】 55 pieces/cell

- 【Cathode Plate Specification】 1050mm×1016mm

- 【Cathode Plate Spacing】 100mm

- 【Cathode Plate Processing Capacity】 200-450 pieces/hour

- 【Unit Weight of Stainless Steel Cathode Plate】 45kg/piece

- 【Electrolyte Composition】 Cu²⁺: 45~50g/L; H₂SO₄: 180~200g/L; Cl⁻: <0.1g/L

- 【Control Method】 PLC

- 【Noise Level】 Below 85dB(A) at 1 meter away from the equipment

Servo - Coordinated Drive Robot Stripping Unit - An Efficient and Intelligent Solution for Cathode Copper Stripping

Developed and Produced by Ganzhou Jinhuan Casting Equipment Co., Ltd.

Product Positioning

The servo - coordinated drive robot stripping unit is a high - end intelligent equipment developed to address the pain points of the cathode copper smelting industry, such as low stripping efficiency, heavy cathode plate damage, high energy consumption, and multiple environmental risks. Relying on the core technology of "multi - axis servo control + robot - like drive", it realizes the high efficiency, intelligence, cleanliness, and safety of cathode copper stripping, providing core support for copper smelting enterprises to reduce costs, increase efficiency, and achieve compliant production. Its technical level has been certified as reaching the leading level in China, making it an ideal upgraded alternative to traditional hydraulic stripping units.

Core Advantages: Addressing Pain Points of Traditional Units and Reshaping the Stripping Experience

1. Zero Damage to Cathode Plates, Significantly Reducing Maintenance Costs

Triple Protection Technology: The stripping knife does not touch the cathode plate + wear - resistant flexible knife body material + intelligent photoelectric closed - loop detection, accurately controlling the deflection deformation of cathode plates and fundamentally preventing scratches and deformation.

Measured Data: During the industrial verification at Zijin Copper Industry, thousands of stripping operations were completed without a single permanent stainless steel cathode plate being damaged. This completely solves the problem of the 0.2% annual damage rate of traditional units (for a production capacity of 50,000 tons per year, it saves more than 180,000 RMB in annual maintenance costs and over 990,000 RMB in plate replacement costs).

Strong Adaptability: Compatible with domestic/imported permanent stainless steel cathode plates (unit price: 1,500 - 3,000 RMB per piece), extending the service life of cathode plates and reducing the cost of core consumables.

2. Efficient and Intelligent Stripping, Leading in Both Speed and Precision

Ultra - High - Speed Stripping: The single - unit stripping speed reaches 5.2 seconds per piece. With two stripping frames operating in coordination, the stripping speed can exceed 700 pieces per hour, far surpassing traditional units and meeting the production needs of large - scale copper smelting.

Flexible Speed Regulation: The linear speed can be adjusted with one click in the range of 0 - 999 mm/s, with millisecond (ms) - level dynamic response, easily adapting to the production requirements of different electrolysis cycles and different cathode copper thicknesses.

Precise Control: Adopting 7 - axis Siemens servo motors, it achieves millimeter (mm) - level positioning accuracy. The stripping action is stable and continuous, and the reliability of continuous operation is improved by more than 30%.

3. Clean and Energy - Saving Drive, Aligning with Green Production

Pollution - Free Cleanliness: Abandoning the traditional hydraulic drive, it adopts a "servo + pneumatic" composite drive, with no oil leakage or oil pollution, ensuring a clean production environment and fully complying with national environmental protection requirements.

Energy Conservation and Consumption Reduction: The servo motor only consumes energy when in operation (on - demand energy consumption). The overall energy consumption of the unit is reduced by more than 20% compared with traditional hydraulic units. Calculated based on 8,000 operating hours per year, it saves more than 100,000 RMB in annual electricity costs (based on an industrial electricity price of 1 RMB per kWh).

4. Safety and Convenience, Low Operation and Maintenance Costs

Safety Design: The stripping frame has a compact structure and reduced height, and the maintenance space can be adjusted to the maximum as needed, allowing maintenance personnel to easily enter and exit for maintenance. There is no risk of hydraulic pipeline explosion, further eliminating potential safety hazards in production.

Easy Operation and Maintenance: Modular design facilitates fault diagnosis; the servo system has high stability, and the failure rate is reduced by 50% compared with the hydraulic system, minimizing downtime for maintenance.

Authoritative Certification: Reliable Technology with Guaranteed Implementation

Industrial Verification

From 2017 to 2018, industrial verification tests were completed at Zijin Copper Industry. The enterprise issued a "Verification Certificate", recognizing its "cleanliness, energy conservation, convenient operation, and safety reliability".

Expert Evaluation

In 2020, evaluated by the China Non - Ferrous Metal Industry Technology Innovation Strategic Alliance, it was confirmed to have "reached the leading level in China in overall technology". Its three core technologies (efficient stripping, intelligent cathode plate protection, and clean energy conservation) were highly recognized by industry experts.

R&D Strength

In - depth cooperation with Jiangxi University of Science and Technology, with 8 years of R&D (project initiation in 2015 - iteration in 2023). The technology has high maturity and has realized large - scale commercial application.

Application Scenarios

- Newly - built/expanded copper smelting projects (production capacity ≥ 50,000 tons per year, complying with the Standards for the Copper Smelting Industry).

- Copper enterprises in need of upgrading and replacing traditional hydraulic stripping units.

- Modern copper smelting plants with high requirements for environmental protection, energy consumption, and production efficiency.

Enterprise Support

Ganzhou Jinhuan Casting Equipment Co., Ltd. focuses on the R&D and manufacturing of high - end equipment for non - ferrous metal smelting. It provides customers with "technical consultation - customized solutions - installation and commissioning - after - sales maintenance" full - cycle services, ensuring the rapid implementation and stable operation of equipment, and helping enterprises reduce costs, increase efficiency, and gain an advantage in the industry competition.

Address: No. 173 Xiangjiang Avenue, Development Zone, Zhanggong District, Ganzhou City, Jiangxi Province, China

Phone/WhatsApp: +86 199 5432 2149

Email: zxszchina@gmail.com

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.